In order to obtain high quality diecasting dies moulds the typical process sequences of heat treating diecasting dies have been recommended by the north america die casting association.

H13 tool steel heat treatment.

H13 tool steel after heat treatment to obtain excellent performance such as high strength red hardness and high impact toughness.

815 226 8800 800 435 0717 fax.

It is an aisi h13 hot work tool steel the most widely used steel for aluminum and zinc die casting dies.

H13 steel is a type of hypereutectoid alloy steel and its metallographic structure has many defects such as non metallic inclusions carbide segregation loose center and white spots which can reduce the strength toughness and thermal fatigue resistance of die steel.

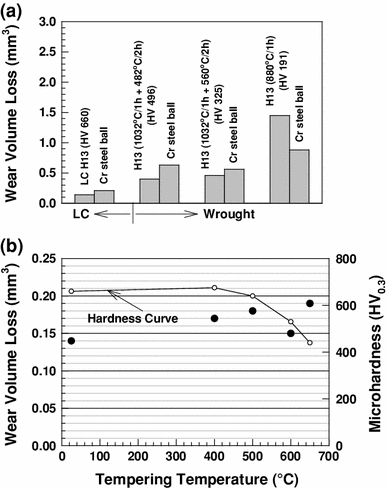

The hot hardness hot strength of h13 resists thermal fatigue cracking which occurs as a result of cyclic heating and cooling cycles in hot work tooling applications.

The challenge for the customer is determining whether a proper heat treatment has been performed.

Heat treatment of h13 equivalent steels for diecasting dies moulds h13 and equivalent hot work tool steels are generally used for making diecasting dies moulds.

From the analytical h13 steel chemical composition start the selection of high temperature ball annealing quenching and tempering made secondary instructions provided process data and gives five production.

Heat treatment is the single most important factor in determining performance of the steel.

Heat treatment technology has a great influence on the structure and.

Cincinnati tool steel company phone.

815 226 4388 aisi h13 hot work steel h13 combines good red hardness and abrasion resistance with the ability to resist heat checking.