They are actually quite common but the good news is that it can be fixed properly as long as you have the right tools and knowledge.

How to fix corrugated steel roofing sheets.

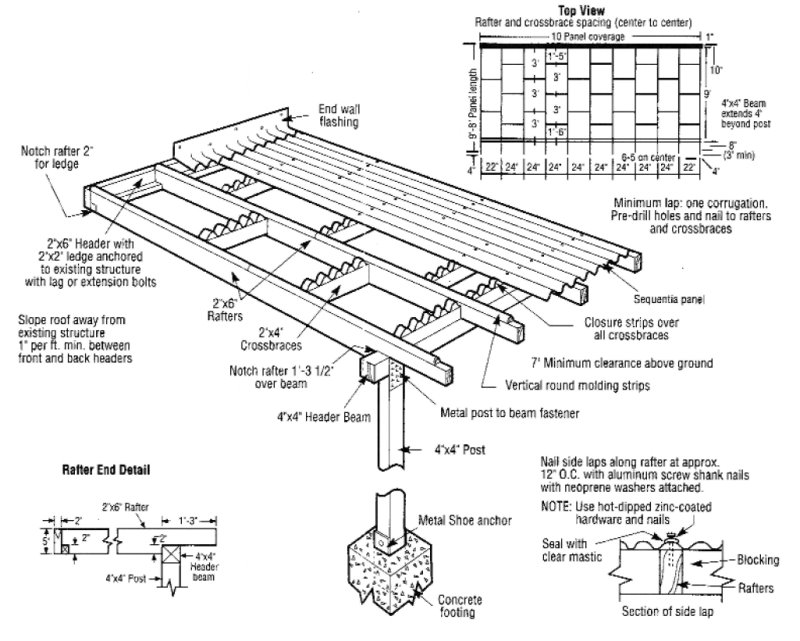

For corrugated sheets the fixings required will depend on the material used in the purlins.

A corrugated roof may be a versatile cheap and popular roofing option among homeowners but this does not mean that it is impervious to leaks.

Corrugations should run in a straight line between the highest and lowest points and at a right angle to the purlins the intermediate supports.

Cut the piece large enough to cover the hole and 6 inches of the surrounding roofing each way using sheet metal cutters.

Corrugated sheet roofing material is widely available and easy to use.

Metal roof sheets for garages tend to come in steel aluminium and zinc and are generally coated with another metal plastic or stone granules to create an aesthetically pleasing finish.

Rather than calling a professional you can personally do the task and save on unnecessary labor costs.

Urethane roof cement is an excellent product that can help you patch holes on corrugated metal roofing.

Steel roofing can be costly but it is a lifetime investment.

Dampen a rag with acetone and wipe the area clean.

Cladco offer a range of fixings.

To fix the sheets each tileform sheet has 5 troughs for securing we recommend you fix the sheet into trough 1 3 and 5.

Metal roofing resists rot is not susceptible to insect damage and is non combustible a boon in fire prone areas.

The overlaps ends and sides depends upon the sloop of the roof.

A corrugated metal roof is quieter than pvc when it rains.

To install corrugated steel roofing sheets the purlin material must be considered.

One downside is that the metal sheets have a susceptibility to denting both in installation and during hailstorms.

Another benefit of metal roofing is that they aren t affected by or susceptible to termites or insects and they are often treated by the manufacturers to.

Patching materials for metal corrugated roofing sheets.

Purlin spacing should suit the end laps required for the size.

Corrugated roofing sheets should be installed into the corrugated sheets crown using a 65mm tek screw with baz washer.

The bottom end of the sheets you can fix in each trough to help prevent wind uplift of the sheets.

Galvanized steel which is created by using a soft layer of zinc to protect the inner layers is the most common type of steel roofing.

Cladco supply fixings for most purlin compositions and thickness.